Key Takeaways:

- Utility locating services use advanced technology like GPR and electromagnetic locators to safely locate gas lines.

- The process involves a site inspection, using non-invasive equipment, and marking the gas lines on the ground.

- Accurate documentation and reports are provided to ensure safety and compliance.

- Preparation includes clearing the area and providing detailed project information to the technician.

- Ongoing support is available for future projects or re-checks of utility locations.

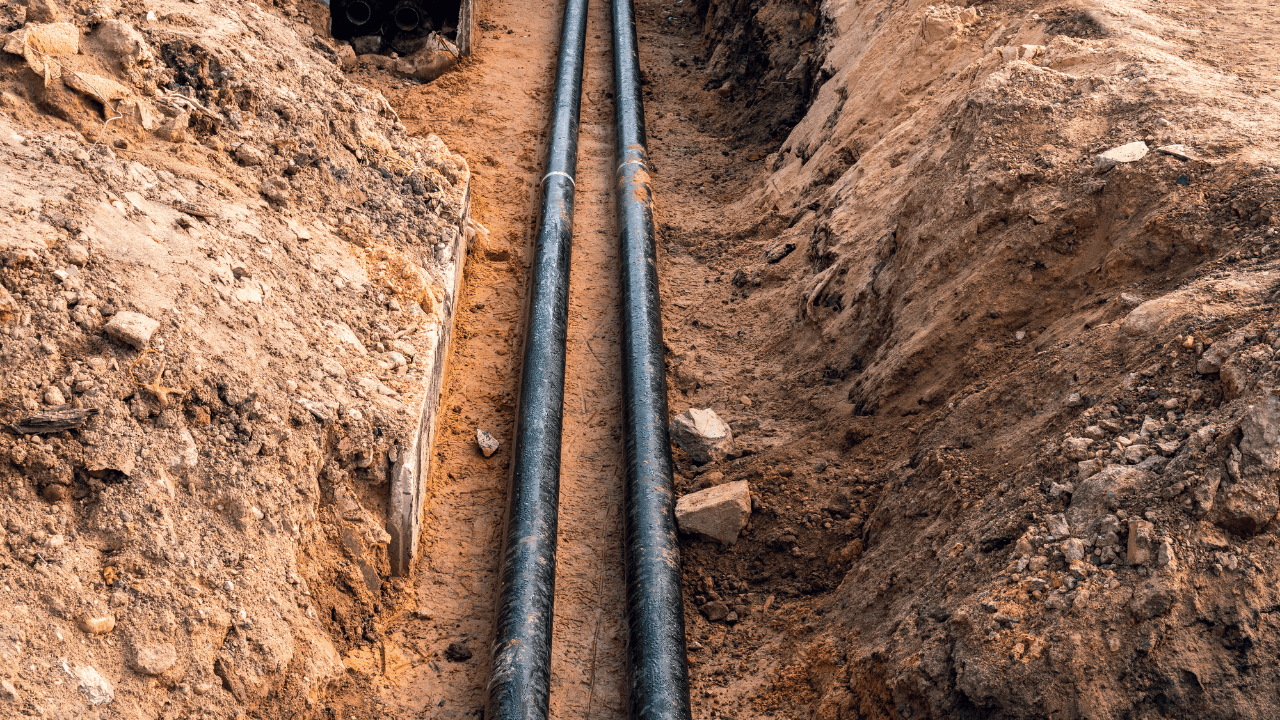

When you’re working on a construction project or performing any kind of excavation work in California, it’s crucial to know exactly where underground utilities, including gas lines, are located. Damaging a gas line can lead to hazardous situations, fines, and costly repairs. This is where professional underground utility locating services come in.

Key points on What to Expect During a Professional Gas Line Utility Locating Service in California are:

- Why Gas Line Locating is Important

- Step-by-Step Guide

- How to Prepare for the Service

- Ensure Safe Excavation with Professional Utility Locating Services

These experts use advanced technologies to accurately locate underground gas lines, ensuring the safety of workers and preventing damage to existing infrastructure. If you’re planning any work that involves digging or excavation, it’s essential to understand the process of utility locating services. In this guide, we’ll explain what to expect during a professional gas line utility locating service and how to prepare for it.

Why Gas Line Locating is Important

Before diving into the specifics of the service, let’s first understand why it’s important to hire a professional underground utility locator. Gas lines are often buried several feet underground, and locating them can be a complicated process. Without proper locating, workers might accidentally hit a gas line, leading to gas leaks, fires, or explosions. Underground utility locating is necessary to ensure that construction, excavation, and other activities avoid these hazardous lines, promoting safety and preventing costly damages.

In California, with its mix of urban and rural areas, precise utility locating is even more critical. High population density means more complex utility networks, making it vital for projects to accurately mark where all the gas lines are.

Step-by-Step Guide: What to Expect During a Professional Gas Line Locating Service

Here’s a step-by-step look at the process of utility locating services for gas lines. Understanding these steps will help you prepare for the service and ensure everything goes smoothly.

Step 1: Initial Consultation and Scheduling

The first step in any underground utility locating service is to get in touch with a professional. During the initial consultation, you will discuss the scope of your project and provide the location where the work is to be done. Whether you’re working on a construction site, renovating a building, or doing a landscaping project, providing clear and accurate details will help the underground utility locator plan for the service.

- What you’ll need to provide:

- Project location and address.

- Details of the planned excavation or digging work.

- Information on any previous utility maps or known utility lines.

Once the details are confirmed, a professional will schedule a time to perform the service. Scheduling is typically done during regular working hours, but emergency services are also available.

Step 2: Site Inspection and Preparation

Once the service is scheduled, the underground utility locator will arrive at your project site. Before using any equipment, they will conduct a thorough site inspection. This step is crucial because it helps the technicians assess the best way to locate the gas lines, taking into account the terrain, existing infrastructure, and any potential hazards.

During this inspection, the team will:

- Evaluate the area for safety.

- Identify any visible surface markings (like prior utility installations).

- Determine if the ground conditions (soil type, moisture levels) will affect the locating process.

The underground utility locator will then prepare the necessary equipment. This typically includes high-tech tools such as Ground Penetrating Radar (GPR) or electromagnetic locators. The preparation phase is critical for ensuring the correct method is chosen to locate the gas lines with high accuracy.

Step 3: Locating Gas Lines Using Advanced Technology

Once the site is prepped, the technicians will begin the actual locating process. The technology used in utility locating services is non-invasive, meaning it doesn’t disrupt the surrounding area or cause unnecessary digging. Here’s a closer look at the main technologies used:

- Ground Penetrating Radar (GPR): This method sends high-frequency radio waves into the ground. The waves bounce back when they hit solid objects like gas lines. By analyzing these signals, GPR can detect the exact location and depth of the gas line.

- Electromagnetic Locators: These devices detect conductive materials such as metal gas pipes. The equipment transmits an electromagnetic field into the ground, and the underground utility locator can pinpoint where the gas lines are located based on the signals received.

Both methods are highly effective and allow the technician to accurately pinpoint the gas lines without any disruption to the surrounding area. The underground utility locator will walk around the site with the equipment, taking measurements and marking the locations of gas lines on the surface.

Step 4: Marking the Gas Lines

After locating the gas lines, the next step is marking them clearly. Technicians will use spray paint, flags, or other visible markers to outline the paths of the gas lines. This is especially important for construction and excavation teams, as it helps avoid accidents during digging.

Typically, different colors of spray paint are used for different utilities:

- Yellow for gas lines.

- Red for electric lines.

- Blue for water lines.

This marking process ensures that workers can see where the gas lines are and take appropriate precautions.

Step 5: Final Report and Documentation

After the gas lines are located and marked, the underground utility locator will provide you with a detailed report. This report typically includes:

- A map or diagram showing the exact locations and depths of the gas lines.

- Detailed documentation on the methods used during the locating process.

- Recommendations for safe excavation if needed.

This report is valuable for ensuring that you have a clear understanding of the gas line locations and can proceed with your project safely.

Step 6: Ongoing Support

Even after the gas line locating service is completed, many professional utility locating services offer ongoing support. For instance, if any additional utilities need to be located in the future or if there’s a need for further excavation work, you can contact the underground utility locator again. Many service providers also offer updates and re-checks if there are any changes to the site or if additional permits or safety measures are required.

How to Prepare for the Service

Now that you know the step-by-step process, here are a few tips to ensure the utility locating service goes smoothly:

- Clear the Work Area: Make sure the area is easily accessible for the technicians and their equipment. Remove any obstacles or debris that could hinder the locating process.

- Provide Accurate Information: The more accurate details you provide about your project location and existing utilities, the smoother the service will go.

- Be Available During the Service: Ensure that someone from your team is available to communicate with the technicians and answer any questions.

- Understand the Marking Process: Be prepared for visible markings on your property. These markers will help protect the gas lines from accidental damage during excavation or digging.

Ensure Safe Excavation with Professional Utility Locating Services

In conclusion, a professional utility locating service is crucial for ensuring safe excavation and construction work, particularly when it comes to gas lines. By hiring a skilled underground utility locator, you can avoid costly mistakes, prevent safety hazards, and ensure that your project proceeds smoothly. Whether you are a contractor, a property owner, or someone undertaking a DIY excavation project, using a professional utility locating service is the best way to protect your investment and ensure the safety of everyone involved.

If you are in California and need reliable, non-invasive underground utility locating, Util-Locate is here to help. With advanced technology, expert technicians, and a commitment to safety, we offer comprehensive utility locating services that you can trust. Contact Util-Locate today to schedule your service and get peace of mind for your next project.