Construction excavation poses various risks that need to be effectively managed to ensure the safety of workers and the success of the project. Understanding these risks and implementing appropriate measures is crucial to maintaining a secure working environment. One essential aspect of excavation is the proper identification and management of underground utilities, which can be achieved through techniques such as potholing utilities.

Utility potholing services involve the careful excavation and exposure of utility lines to accurately locate and protect them during the construction process. By integrating potholing techniques and following industry standards, construction companies can minimize the risk of potential hazards, such as collapse, electrical incidents, and ground movement.

This blog will provide an overview of the safety hazards associated with excavation and offer insights into effective strategies for managing these risks. From excavation safety practices to the implementation of non-destructive methods, including potholing utilities, this information will equip construction teams with the knowledge needed to ensure a safe and successful excavation project.

Excavation Hazards on Construction Projects: Identifying and Mitigating Potential Risks

Construction excavation entails various hazards that can pose threats to worker’s safety and project success. Identifying and mitigating these potential hazards is crucial for maintaining a secure work environment. Common safety hazards include:

- Collapse: Excavation walls can cave in due to unstable soil conditions or inadequate support systems, leading to serious injuries or fatalities. Proper shoring and shielding techniques are essential to preventing collapse hazards.

- Utility Strikes: Accidental damage to underground utility lines, such as water pipes, gas lines, or electrical cables, can cause service disruptions, injuries, or even explosions. Effective utility locating techniques, like potholing in construction projects, are vital for accurate identification and safe excavation near utilities.

- Ground Movement: Excavation activities can cause ground displacement or settlement, resulting in sinkholes or structural damage to nearby buildings. Monitoring and managing ground movement risks through geotechnical assessments and proper engineering controls is crucial.

To mitigate these risks, contractors or construction companies should implement comprehensive safety measures, including thorough site inspections, effective communication, proper training, and adherence to industry regulations and standards.

Regular monitoring and evaluation of work conditions can help identify and address potential hazards promptly, ensuring a safer excavation environment.

Promote Excavation Safety Through Best Practices for Construction Sites

Ensuring excavation safety is paramount for construction sites to protect workers and maintain project timelines. Implementing best practices is crucial to minimizing risks and creating a secure working environment. Key considerations for promoting excavation safety include:

- Pre-Planning – Adequate planning is essential to assess potential hazards, determine appropriate protective measures, and create a detailed excavation plan. This includes conducting utility location surveys, evaluating soil conditions, and identifying required safety equipment.

- Proper Training: All personnel involved in excavation activities should receive comprehensive training on excavation safety protocols, hazard recognition, proper equipment usage, and emergency procedures. Ongoing training and regular safety meetings help reinforce safe practices.

- Protective Equipment: Personal protective equipment (PPE) plays a vital role in excavation safety. Workers should be equipped with appropriate PPE, such as hard hats, safety boots, high-visibility clothing, and respiratory protection, based on the specific hazards present at the excavation site.

- Excavation Inspections: Regular inspections of excavation sites ensure compliance with safety standards and identify any potential hazards or deficiencies. Inspections should cover excavation stability, proper barricading, secure spoil piles, and the presence of utility markings.

- Emergency Response: Adequate emergency response plans should be in place, including procedures for evacuation, first aid, and contacting emergency services. All workers should be aware of the emergency response protocols and the location of emergency equipment.

By following these best practices, construction sites can create a culture of safety, reduce accidents and injuries, and enhance productivity during excavation projects.

Potholing Techniques for Safe Utility Location in Construction Excavation

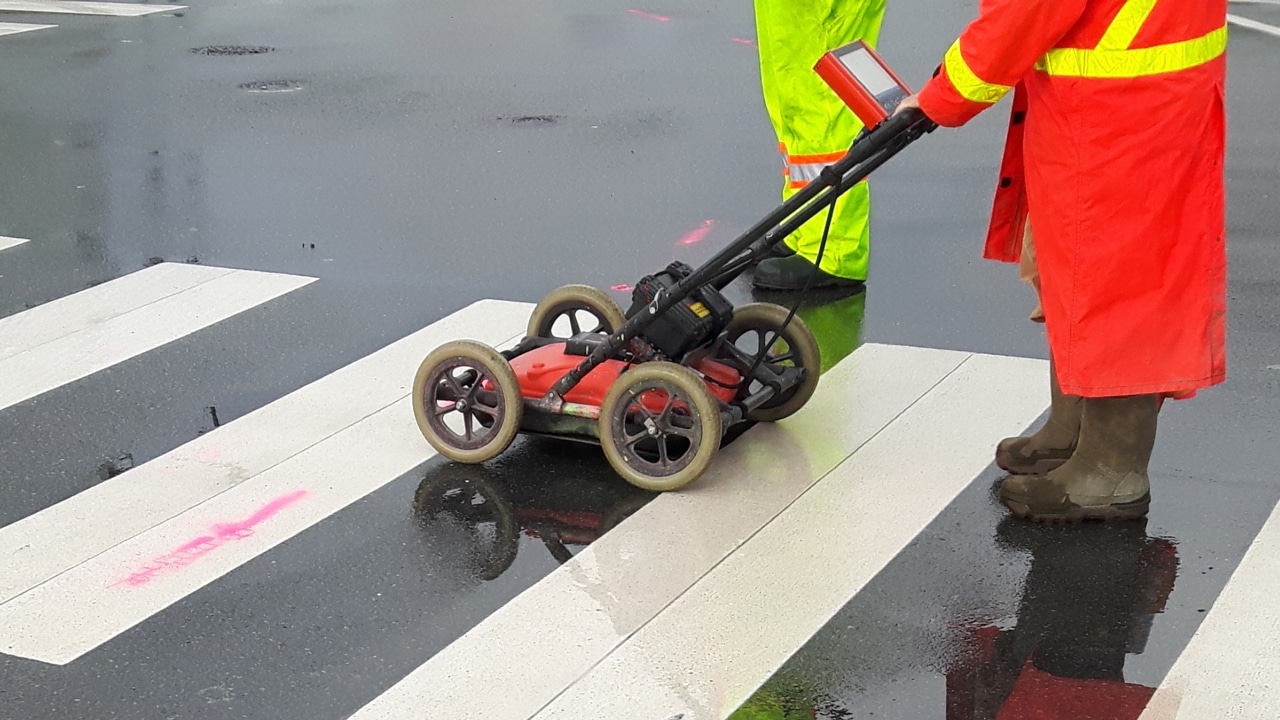

Accurate utility location is vital to preventing damages and ensuring worker safety during construction excavation. Potholing techniques, also known as utility potholing or daylighting, are effective methods for precisely identifying the location of underground utilities.

These techniques involve the controlled excavation of small holes to expose utility lines without causing any damage. Common potholing techniques include:

- Vacuum Excavation: This method utilizes a vacuum excavator that suctions soil and debris from the excavation area, providing a clear view of the utility lines. Vacuum excavation is a non-destructive method that minimizes the risk of utility damage and maximizes precision.

- Hydro Excavation: Hydro excavation uses pressurized water to break up the soil, which is then removed by vacuum. It is particularly useful in areas where the soil is compacted or in sensitive environments where minimal disturbance is required.

- Hand Digging: In certain situations, hand digging may be employed, especially in locations with limited access or where delicate utilities are present. Hand digging allows for careful excavation by skilled workers using shovels or hand tools.

By utilizing potholing techniques, construction teams can accurately locate underground utilities, minimize the risk of utility strikes, and ensure a safe and efficient excavation process.

The Role of Industry Standards: Ensuring Safety in Construction Excavation

The construction industry relies on industry standards to ensure safety during excavation projects. These standards play a crucial role in establishing guidelines and best practices that promote a safe working environment. They encompass various aspects of excavation, including equipment usage, protective measures, and work procedures.

Industry standards provide a framework for construction companies to assess potential hazards, implement necessary safety measures, and train workers accordingly. They outline requirements for proper excavation techniques, equipment maintenance, and the use of personal protective equipment. Adhering to these standards helps mitigate risks, prevent accidents, and protect workers from harm.

Manage Construction Excavation Risk with Util-Locate Today!

Ensure the safety and success of your construction excavation projects with Util-Locate. Our team of experts is dedicated to managing excavation risks and implementing industry-leading safety practices. By choosing Util-Locate, you can benefit from our extensive experience in potholing for utilities and underground utility location.

We utilize advanced techniques and non-destructive methods to accurately locate utilities, minimizing the risk of damage and potential hazards. Our commitment to industry standards and safety regulations ensures that your excavation projects are conducted with the utmost care and compliance.

Don’t compromise on safety. Trust Util-Locate to manage construction excavation risks effectively. Contact us today at 888-885-6228 to discuss your project requirements and learn more about our comprehensive solutions for safe and efficient utility location. Together, we can create a secure working environment and achieve successful excavation outcomes.