Key Takeaways

- Frozen Ground Changes Tool Performance: Utility locating tools lose 50% accuracy in cold-weather excavation. GPR improves while EM locators struggle—underground utility locating needs winter-adapted technology.

- Multi-Tool Integration Essential: No single technology works alone. Utility locators combine GPR, EM, GPS, and hydro-vacuum for reliable cold-weather excavation detection.

- Pre-Winter Preparation Prevents Failures: Complete underground utility locating before the ground freezes. GPS-tagged markers maintain accuracy when snow buries physical markings.

- AI Overcomes Frozen Ground Interference: Machine learning compensates for ice automatically. AI-enhanced utility locating tools improve accuracy while reducing expertise requirements for utility locators.

- Hydro-Vacuum Eliminates Strike Risk: Heated water excavation confirms utilities definitively. Non-destructive exposure works in any cold-weather excavation condition regardless of frost depth.

Frozen ground fundamentally alters the physics that standard utility locating tools depend on for underground utility locating accuracy. When soil freezes, its electrical resistivity increases dramatically while conductivity drops—creating conditions that starve electromagnetic utility locators of the ground connection they need to complete signal circuits. Snow and ice form physical barriers between equipment and ground surface, disrupting antenna coupling for GPR systems and obscuring the surface markers that guide cold-weather excavation. Temperature fluctuations compound these challenges by causing ground heaving and pipe contraction, shifting utilities 6-12 inches from their marked positions. The result: utility locating tools calibrated for temperate conditions lose 50% or more of their detection accuracy when winter arrives.

Moisture variations create additional interference for underground utility locating techniques throughout the cold season. High moisture content from melting snow attenuates GPR signals, reducing penetration depth and image clarity just when precision matters most. For electromagnetic utility locators, changing soil moisture alters the electromagnetic field’s shape and strength, producing inconsistent readings that confuse even experienced operators. Frozen ground becomes too hard for standard probe insertion—techniques that work perfectly in summer become physically impossible in cold-weather excavation. Standard utility locating tools aren’t designed for these extreme conditions, which is why professional cold-weather excavation demands specialised equipment and adapted underground utility locating techniques that account for frozen soil physics.

What Are the Main Categories of Cold-Weather Utility Locating Tools?

Professional cold-weather excavation requires specialized utility locating tools that maintain accuracy despite frozen ground interference. The five essential categories below represent the core technologies for underground utility locating in winter conditions. Each tool type offers distinct advantages for specific utility locators working in sub-zero temperatures, and understanding their winter performance guides proper equipment selection for reliable underground utility locating techniques.

| Utility Locating Tool Type | Primary Functionality | Winter Performance Rating |

| Ground Penetrating Radar (GPR) | Sends high-frequency radio waves into the ground to detect metallic and non-metallic utilities through subsurface imaging | Excellent – Low moisture content and high electrical resistivity of frozen ground actually improve signal penetration depth and image clarity for underground utility locating |

| Electromagnetic (EM) Locators | Induces current onto conductive utilities; receiver detects electromagnetic field to trace metal pipes and cables | Moderate – Reduced soil conductivity weakens signals, but multi-frequency transmitters and advanced filtering overcome frozen ground limitations for utility locators |

| Hydro-Vacuum Excavation | Uses heated water and an industrial vacuum to thaw and remove frozen soil without mechanical contact | Excellent – Non-destructive exposure works in any cold-weather excavation condition; eliminates utility strike risk through precise underground utility locating verification |

| GPS/GIS Integration Systems | Collects field data with geographic coordinates; creates 3D maps and permanent digital utility records | Excellent – Electronic marking unaffected by snow cover; provides weather-proof underground utility locating documentation when physical markers are buried |

| AI-Enhanced Signal Processing | Machine learning algorithms interpret complex GPR/EM data; filter false positives from frozen ground reflections | Excellent – Automatically compensates for ice interference and moisture variations; reduces expertise required for accurate cold weather excavation utility detection |

These utility locating tools work most effectively when combined—no single technology solves all underground utility locating challenges in frozen conditions. Professional utility locators deploy multiple tools simultaneously, using GPS/GIS systems to document findings from GPR and EM equipment while AI processing improves real-time accuracy during cold-weather excavation operations.

What Are the Most Effective Tools for Cold Weather Utility Locating?

The three most critical utility locating tools for cold-weather excavation have proven track records in frozen ground conditions. Multi-frequency GPR systems excel where other underground utility locating techniques fail, electromagnetic locators maintain functionality with proper adaptations, and hydro-vacuum excavation provides definitive verification when detection accuracy matters most. Professional utility locators combine these technologies strategically, matching each tool’s strengths to specific site conditions and utility types during underground utility locating operations.

How Do Multi-Frequency GPR Systems Work in Frozen Ground?

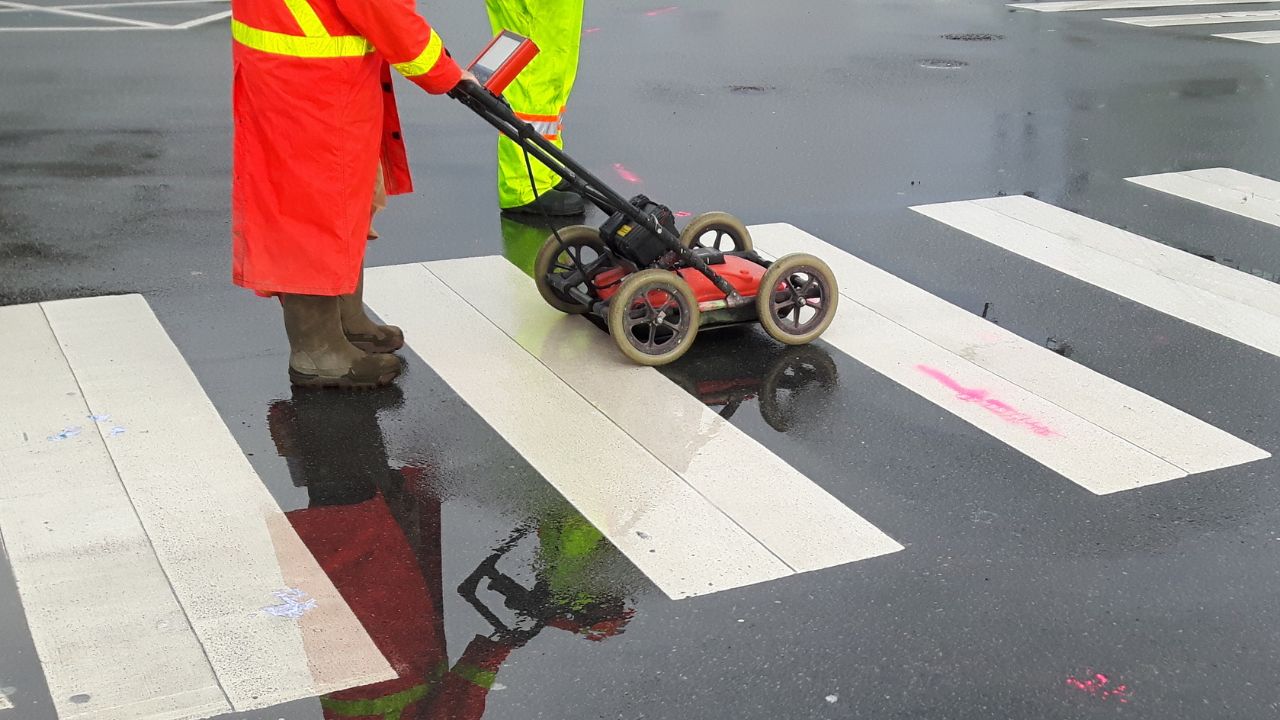

Multi-frequency GPR systems dominate cold weather excavation because frozen ground actually improves their performance. These utility locating tools transmit radio waves across frequency ranges from 100-900 MHz, with lower frequencies penetrating deep through frozen soil while higher frequencies provide detailed resolution at shallow depths. The low moisture content and high electrical resistivity of frozen ground reduce signal attenuation—the primary enemy of GPR in summer conditions. This allows radio waves to penetrate deeper and produce clearer subsurface images during underground utility locating operations. Professional utility locators adjust frequency selection based on target depth: 100-200 MHz for utilities buried below frost lines, 400-900 MHz for shallow infrastructure detection in frozen zones.

Challenges remain despite GPR’s winter advantages. Heavy snow cover affects antenna-to-ground coupling, requiring utility locators to clear excavation areas before scanning. The transition zone between frozen and thawed soil creates complex reflections that confuse interpretation—this is where AI-enhanced signal processing becomes essential for accurate underground utility locating. Post-processing software compensates for ice signal distortion and dielectric property changes that vary across job sites. Modern GPR utility locating tools include real-time depth correction algorithms that adjust readings automatically as frozen ground conditions shift. When properly deployed with multi-frequency scanning and advanced processing, GPR provides the most reliable cold-weather excavation detection available.

What Makes Cold-Weather Electromagnetic Locators Essential?

Electromagnetic locators remain essential utility locating tools despite frozen ground challenges because they detect conductive utilities that GPR sometimes misses. These systems consist of a transmitter that induces electrical current onto target utilities and a receiver that traces the resulting electromagnetic field. Active locating connects the transmitter directly to utilities or uses an inductive clamp, while passive locating detects existing fields from live power cables. The functionality makes EM locators indispensable for underground utility locating on metallic pipes and cables, where precise tracing is required during cold-weather excavation projects.

Frozen soil significantly impacts EM locator performance through reduced conductivity that weakens signal propagation. The electrical circuit required for signal completion struggles in frozen ground where utility locators cannot establish proper ground connections. Modern solutions overcome these limitations through multi-frequency transmitters that select optimal frequencies for resistive frozen soil conditions. Advanced filtering algorithms distinguish utility signals from interference created by ice layers and moisture variations. Some sophisticated utility locating tools transmit multiple frequencies simultaneously, providing more complete subsurface pictures during underground utility locating operations. Professional utility locators now deploy specialised grounding equipment designed specifically for cold-weather excavation—establishing connections through ice and frozen soil where standard ground rods fail completely.

Why Is Hydro-Vacuum Excavation the Gold Standard?

- Non-destructive utility exposure eliminates strike risk—heated water and industrial vacuum remove frozen soil without mechanical contact, providing definitive verification for underground utility locating when detection alone isn’t sufficient for cold weather excavation safety

- Freeze-proof operation in any winter condition—works effectively at any temperature where utility locating tools struggle; thaws and excavates simultaneously regardless of frost depth or soil type during underground utility locating operations

- Precise verification utility locators cannot provide alone—exposes exact utility positions, depths, and configurations that detection equipment estimates; confirms underground utility locating accuracy before mechanical excavation begins

- OSHA-approved method for cold weather excavation compliance—meets federal requirements for exact location determination; provides legal documentation that proper underground utility locating techniques were followed during frozen ground projects

- Cost-effective despite premium pricing—prevents utility strikes costing $75,000-$500,000+ each; hydro-vac investment pays for itself by eliminating damage that destroys cold-weather excavation budgets and project timelines for utility locators

What Pre-Winter Preparation Techniques Maximize Success?

Successful cold weather excavation begins weeks before the ground freezes. Professional utility locators implement these preparation techniques to maintain underground utility locating accuracy throughout winter. Early planning prevents the detection failures and marking losses that plague contractors who wait until frozen conditions force reactive solutions. These underground utility locating techniques ensure that utility locating tools operate at peak performance when winter arrives.

- Schedule all underground utility locating before consecutive freezing days—complete detection and marking 2-4 weeks before anticipated frost penetration; utility locating tools achieve maximum accuracy in unfrozen soil before cold-weather excavation challenges begin

- Pre-mark sites with high-visibility cold-weather materials—use black paint and taller flags that remain visible against snow; standard color-coded markers disappear under winter conditions, eliminating the visual guides that utility locators depend on

- Document utility positions with GPS coordinates before snow—create permanent electronic records unaffected by weather; GPS-tagged digital markers provide backup when physical markings buried during cold weather excavation operations

- Photograph all marking locations for winter reference—visual documentation helps utility locators relocate buried markers; images combined with GPS data ensure underground utility locating accuracy persists despite snow accumulation

- Install elevated marker systems on snow-free structures—place flags and reflective stakes on posts, fences, or equipment that remain above expected snowfall; maintain visibility for utility locating tools throughout winter

- Create detailed site maps integrating all detection data—combine GPR, EM locator, and GPS information into a comprehensive GIS database before terrain is obscured; centralized underground utility locating documentation accessible during cold weather excavation regardless of field conditions

- Verify utility depths relative to expected frost lines—document whether infrastructure sits above, within, or below anticipated frost penetration (18-48 inches); inform which utility locating tools and underground utility locating techniques are required for winter access

- Establish GIS system access for all stakeholders—ensure excavation crews, utility locators, and project managers can retrieve digital records remotely; real-time data sharing prevents cold-weather excavation delays when physical site access is restricted by weather

What Detection Adjustment Techniques Work in Frozen Conditions?

Standard utility locating tools require significant operational adjustments for accurate cold-weather excavation detection. Professional utility locators modify equipment settings, scanning procedures, and verification protocols to compensate for frozen ground interference. These underground utility locating techniques multiply equipment effectiveness in winter, the difference between successful detection and costly utility strikes during frozen ground projects.

- Start GPR scans with lowest frequency settings (100-200 MHz)—maximizes penetration through frozen ground layers for deep utility detection; utility locating tools achieve better depth performance in ice-affected soil with lower frequencies during cold weather excavation

- Increase frequency incrementally for shallow utility resolution—switch to 400-900 MHz when targeting infrastructure within the frost zone; higher frequencies provide the detail underground utility locating requires for precise positioning near the surface

- Extend dwell time per GPR scan point—frozen ground requires 2-3x longer signal processing than thawed soil; rushing scans reduces underground utility locating accuracy when utility locators need it most during cold weather excavation

- Use maximum EM locator transmitter power settings—overcome reduced frozen soil conductivity with the highest available output; full power compensates for weak signal propagation that limits utility locating tools in resistive winter conditions

- Establish multiple ground connections for EM locators—distribute signal through several contact points when a single connection fails in frozen soil; specialized grounding equipment improves underground utility locating reliability for utility locators

- Deploy multi-frequency EM scanning simultaneously—transmit multiple frequencies at once for a complete subsurface picture; advanced utility locating tools provide comprehensive data that single-frequency systems miss during cold-weather excavation

- Conduct parallel detection passes 3 feet apart—redundant scanning verifies initial findings and catches utilities shifted by ground heaving; cross-checking improves underground utility locating confidence in freeze-thaw affected zones

- Compare field readings with pre-freeze GPS coordinates—verify current detections match documented positions; discrepancies indicate ground movement requiring adjusted underground utility locating techniques from utility locators

- Cross-verify with acoustic detection on pressurized lines—sound propagation works when EM and GPR are challenged by extreme frozen conditions; acoustic utility locating tools provide backup verification during difficult cold weather excavation scenarios

- Use thermal imaging for shallow warm utilities (0-3 feet)—temperature differential between warm infrastructure and frozen ground enhances detection; thermal cameras supplement primary underground utility locating techniques when utility locators need additional confirmation.

What Equipment Maintenance Ensures Winter Reliability?

Utility locating tools fail catastrophically in cold weather excavation without proper winterization. Equipment designed for temperate conditions experiences power failures, component damage, and accuracy degradation when temperatures drop. Professional utility locators implement comprehensive maintenance protocols before winter, preventing mid-project failures that halt underground utility locating operations and expose sites to utility strike risks during frozen ground conditions.

- Switch to cold-weather hydraulic and engine fluids rated to -40°F—standard oils thicken and fail in extreme cold; proper fluids maintain utility locating tools functionality throughout cold weather excavation, regardless of temperature extremes

- Carry 3x normal battery quantity for extended operations—cold reduces battery capacity by 50%; redundant power systems ensure utility locators maintain continuous underground utility locating capability when equipment drainage accelerates

- Pre-warm batteries to room temperature before installation—cold batteries deliver minimal power even when fully charged; warming maximizes available capacity for utility locating tools during cold weather excavation operations

- Store equipment in heated environments between uses—prevents cold-soak damage to electronics and extends component life; heated storage maintains utility locating tools at operational readiness for underground utility locating deployments

- Use insulated carrying cases with chemical warmers—maintains equipment temperature during transport and field breaks; thermal protection prevents utility locators’ detection systems from freezing mid-project during cold weather excavation

- Monitor battery voltage continuously during operations—cold accelerates power drain, making sudden failures likely; real-time monitoring allows utility locators to replace batteries before equipment shutdown disrupts underground utility locating

- Calibrate utility locating tools specifically for frozen ground—manufacturer settings assume temperate conditions; winter calibration adjusts sensitivity for ice interference and signal attenuation during cold weather excavation detection

- Maintain backup equipment on-site for critical projects—redundant utility locating tools prevent project delays when primary systems fail; backup capability is essential for underground utility locating operations where utility locators cannot afford detection gaps in frozen conditions

What Technological Advancements Improve Detection?

Artificial intelligence revolutionizes how utility locating tools interpret complex winter data. Machine learning algorithms like YOLOv5 automatically detect and classify underground utilities from GPR images, filtering the false positives that frozen ground reflections create during cold weather excavation. AI-enhanced signal processing recognizes complex signatures in cluttered environments where ice layers and moisture variations confuse human operators. The technology learns to compensate automatically for transition zones between frozen and thawed soil—the most challenging conditions utility locators face during underground utility locating operations. This significantly reduces the time and expertise required for accurate data analysis, allowing utility locators to deploy underground utility locating techniques that previously demanded years of specialized training. AI systems process data in real-time, providing immediate feedback that guides equipment adjustments and scanning procedures during active cold weather excavation projects.

Geographic Information Systems (GIS) and Global Positioning Systems (GPS) integration transforms underground utility locating from temporary field markings into permanent digital infrastructure maps. Field data collected with precise coordinates uploads instantly to central GIS databases, creating 3D subsurface models accessible to all stakeholders through IoT connectivity. When snow buries physical markers, utility locators retrieve exact positions from GPS-tagged digital records unaffected by weather. Thermal imaging advances now penetrate deeper through frozen soil, detecting warm utilities where the temperature differential is most pronounced in cold-weather excavation conditions. Acoustic detection improvements help frozen ground become denser and more homogeneous—sometimes actually improving sound propagation for pressurized line tracing.

These complementary utility locating tools work together, with GIS platforms integrating thermal, acoustic, GPR, and EM data into unified underground utility locating systems that utility locators access remotely during winter projects.

Integrated Approach to Cold Weather Utility Locating

No single utility locating tool solves all cold-weather excavation challenges—successful underground utility locating demands integrated technology deployment. Frozen ground creates advantages for GPR systems while hindering electromagnetic detection, requiring utility locators to combine multiple tools strategically.

Real-world applications prove this approach works in the harshest environments: utility locating companies in Alaska use specialized GPR mounted on sledges to locate Tanana River channels through thick ice, Canadian operators maintain year-round underground utility locating accuracy with multi-frequency systems and GPS integration, and Antarctica projects demonstrate that proper utility locating tools function reliably even in extreme sub-zero conditions. These operations succeed because utility locators understand that frozen ground isn’t just harder soil—it’s a fundamentally different detection environment requiring adapted underground utility locating techniques.

The key is matching specific site conditions to appropriate technology combinations during cold weather excavation planning. AI-enhanced signal processing, multi-frequency sensors, and GIS integration make underground utility locating increasingly precise regardless of season. When utility locators deploy GPR for its frozen ground advantages, supplement with EM locators for conductive utility verification, confirm positions through GPS-tagged digital mapping, and verify critical infrastructure with hydro-vacuum excavation, they create redundant detection systems that compensate for each technology’s winter limitations. This integrated approach—combining advanced utility locating tools with systematic planning and adapted underground utility locating techniques—ensures essential cold weather excavation continues safely and effectively through the harshest conditions.

Get Professional Cold Weather Utility Locating Tools and Expertise

Cold weather excavation demands specialized utility locating tools and experienced utility locators who understand frozen ground physics. Util-Locate delivers comprehensive underground utility locating services with multi-frequency GPR systems, cold-weather rated EM locators, hydro-vacuum excavation capabilities, and AI-enhanced detection—all backed by GPS/GIS integration for permanent digital documentation.

Our utility locators deploy proven underground utility locating techniques specifically adapted for frozen conditions. We maintain full equipment redundancy, cold-weather calibration protocols, and 24-hour emergency response for critical cold weather excavation projects. When standard utility locating tools fail in winter, Util-Locate’s specialized equipment and expertise keep your projects safe and compliant.

Contact Util-Locate today for utility locating services that work in any cold weather excavation condition—protecting your workers, infrastructure, and budget through the harshest winter.