Key Takeaways

- Winter Amplifies Utility Strike Risks Frozen ground, snow cover, and cold temperatures reduce locating equipment accuracy by 50% or more. Every 9 minutes, a utility is damaged—winter makes this worse.

- Frozen Ground Changes Emergency Response Gas doesn’t dissipate upward through frozen soil—it migrates laterally into buildings. The Minnesota explosion killed 4 people within 40 minutes of the initial strike.

- 811 Doesn’t Cover Everything Public utility marking through 811 is mandatory, but incomplete. Private utilities and abandoned lines require separate professional utility locating services.

- Hydro-Vacuum Excavation Eliminates Strike Risk. Heated water thaws frozen ground and safely exposes utilities to 60 feet. It’s OSHA-approved and virtually eliminates accidental utility damage.

- Call 911 First After Any Utility Strike. Don’t just notify your supervisor—call 911 immediately, then the utility company. Proper emergency response in the first minutes prevents explosions and saves lives.

Winter conditions directly interfere with underground utility locating equipment and create dangerous hazards that multiply risks. Cold temperatures, frozen ground, and snow cover reduce accuracy for utility locators while shortening safe work windows. These challenges make winter the most dangerous season for utility location in California and across the nation.

How Winter Complicates Utility Locating

Impact on Equipment and Accuracy

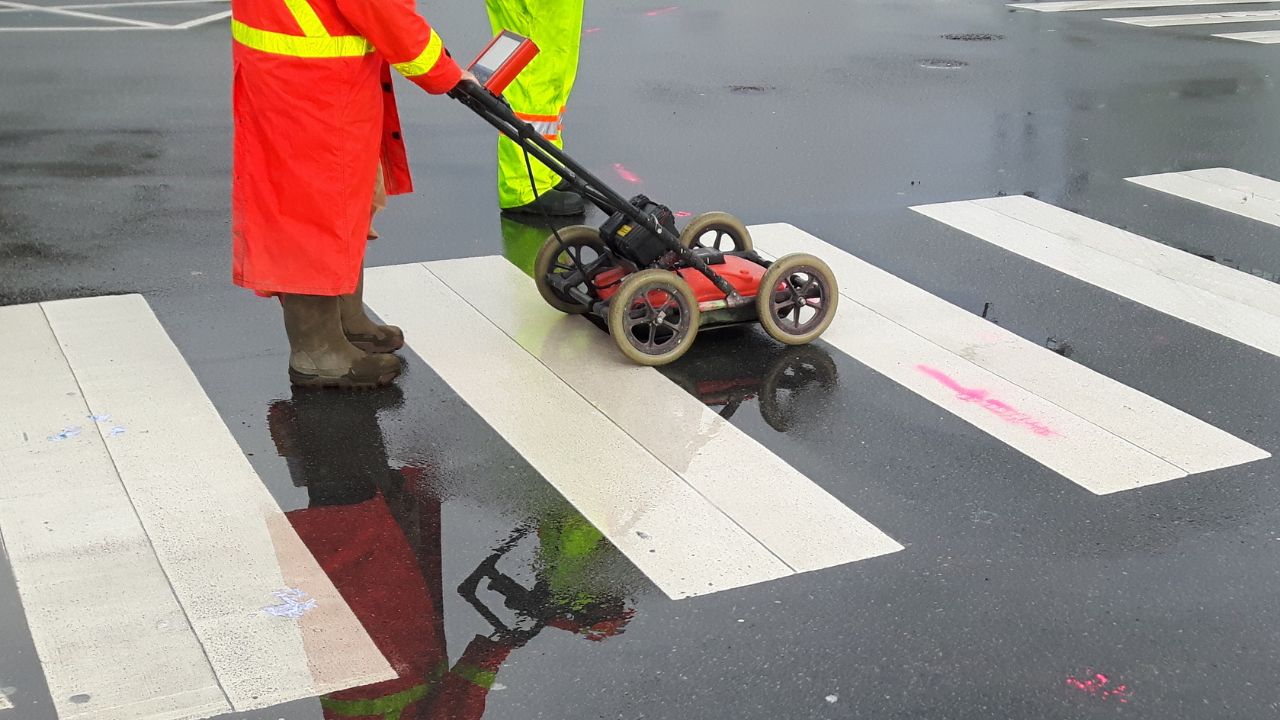

Every 9 minutes, an underground utility line is damaged somewhere in the United States. Winter amplifies this risk by degrading the performance of utility locating services. Frozen soil reduces conductivity, making electromagnetic detection difficult for utility locators tracing metallic pipes and cables. Ice and frozen ground create signal attenuation and scattering for Ground Penetrating Radar (GPR), reducing penetration depth and clarity when scanning for underground utilities.

Snow cover creates additional obstacles for accurate utility location. It obscures utility markers and creates air gaps between GPR antennas and the ground surface, distorting signal timing and depth calculations. Cold temperatures drain battery power—equipment may operate at only half strength, causing failures mid-project. Temperature variations cause buried pipes and cables to contract, shifting their actual positions away from recorded locations.

Winter-Specific Hazards

Shortened daylight hours compress work windows, increasing accidents in low-light conditions. In 2022 alone, 213,792 utility damages were reported, costing approximately $30 billion annually—and winter conditions drive these numbers higher. Frozen soil presents a deadly trap: it can break off in large slabs without warning, causing trench collapses that crush workers. Emergency repairs for burst pipes create intense pressure to rush, increasing the likelihood of skipping proper utility locating services altogether.

| Winter Challenge | Equipment Impact | Safety Risk |

| Frozen Ground | Reduces soil conductivity; blocks GPR signals | Unpredictable collapse of frozen slabs; harder to access utilities |

| Snow Cover | Obscures markers; distorts GPR timing with air gaps | Hidden excavation hazards; limited visibility of safe zones |

| Cold Temperatures | Battery performance drops 50%; equipment failure | Cold-weather injuries (frostbite, hypothermia) |

| Short Daylight | Compressed work windows | Rushing leads to mistakes; working in the dark increases falls |

These combined challenges make professional underground utility locating essential during the winter months. The risks are too high for improvisation.

What Do Winter Utility Accidents Reveal?

Real-world accidents demonstrate the lethal consequences of inadequate underground utility locating during winter. Frozen ground changes how gas disperses, creates unpredictable collapse risks, and tempts contractors to rush past safety protocols. These cases prove that proper utility locating services aren’t optional—they’re the difference between completed projects and tragedy.

Minnesota Gas Pipeline Explosion

A contractor severed a buried natural gas pipeline with digging equipment in Minnesota. The critical error wasn’t hitting the line—it was reporting the leak to a supervisor but NOT to 911 or the utility company. Within 40 minutes, gas migrated through frozen ground into a nearby building and exploded. Four people died. Eleven were injured. Six buildings were destroyed.

Frozen ground prevents gas from dissipating upward into the atmosphere. Instead, it migrates laterally through soil, accumulating in basements and structures with explosive potential. This incident proves that winter conditions fundamentally change emergency response requirements for utility location incidents.

Frozen Ground Trench Collapses

OSHA Case 201751450 documents a worker’s death when a frozen road base slab—just 2 feet wide—fell and crushed him. The slab appeared stable until it suddenly broke free. In Michigan Case 109, a 50-year-old construction worker died in March when frozen soil broke off during excavation and struck him in the back. Both accidents occurred despite standard safety measures.

Frozen soil creates unpredictable collapse hazards. What appears solid can fracture without warning. Underground utility locating becomes exponentially more dangerous when excavation must occur in these conditions—proper utility locators understand these risks and adjust procedures accordingly.

Missouri Industrial Park Strike

A Missouri contractor began digging one day before the scheduled utility marking date at an industrial park. Impatience led to striking a 6-inch high-pressure gas line. The line was capped within 2 hours with no injuries, but only luck prevented catastrophe.

This incident highlights a common winter problem: pressure to maintain schedules despite weather delays tempts contractors to skip utility locating services. Waiting 24 hours for a proper utility location in California—or any state—can prevent disasters that cost millions and destroy lives. Rushing past professional underground utility locating is never worth the risk.

What Are the Essential Winter Safety Practices?

Preventing winter utility accidents requires proactive planning, proper equipment preparation, and worker protection. Professional utility locating services must be scheduled before conditions deteriorate. Equipment must be winterized for frozen ground. Workers need protection from cold-weather injuries. These practices reduce risks and keep projects on schedule despite harsh conditions.

Pre-Planning Requirements

Schedule underground utility locating BEFORE ground freezes. Once the soil freezes solid, detection accuracy drops, and excavation becomes exponentially more dangerous. Call 811 at least 2 business days before excavation—this is federal law. Pre-mark your excavation area with black paint or flags before snow accumulation buries the site. Black markings remain visible against white snow when standard colors disappear.

Build 23-28 weather-related delay days into project timelines. Winter weather will cause stoppages—planning for them prevents dangerous rushing. Critical point: 811 only covers public utilities. Private utilities require separate professional utility locators. Skipping private utility locations in California or any state leaves you blind to significant underground infrastructure.

Cold-Weather Equipment Preparation

Switch to cold-weather hydraulic and engine oils rated for below-zero temperatures. Standard oils thicken and fail in extreme cold. Check batteries before every use—they operate at only 50% capacity in cold weather. Weak batteries cause mid-project failures that halt utility locating services and excavation work.

Swap to digging attachments with sharper, stronger teeth designed for frozen ground penetration. Use block heaters for engines to prevent starting failures on cold mornings. Never use compact equipment on frozen ground—breaking through requires maximum power. Undersized equipment can’t penetrate frozen soil and risks damaging underground utilities that proper utility locators have marked.

Worker Protection Protocols

Equip workers with moisture-wicking base layers. Even in frigid temperatures, intensive digging causes sweating—wet clothing accelerates hypothermia. Layer clothing for insulation but keep it loose-fitting for a full range of motion. Restricted movement slows work and creates safety hazards during utility location verification and excavation.

Provide hats, gloves, and earmuffs to reduce bare skin exposure. Make chemical hand-warmers available on site for all crew members. Schedule regular breaks to prevent frostbite, chilblains, and hypothermia. Cold-weather injuries disable workers and increase accidents. Protecting your crew protects your project timeline and reduces liability when working with utility locating services during the winter months.

What Is the Safest Method for Winter Excavation?

Hydro-vacuum excavation is the safest winter excavation method available. It eliminates the guesswork and danger of digging through frozen ground near buried utilities. When combined with professional utility locating services and proper OSHA compliance, hydro-vacuum excavation virtually eliminates utility strikes while maintaining productivity in extreme cold.

Hydro-Vacuum Excavation Benefits

Hydro-vacuum excavation uses high-pressure heated water to immediately thaw frozen ground. The water creates a slurry that’s evacuated through an industrial vacuum system—no mechanical digging required. This closed-loop system minimizes contamination risk to the surrounding soil and groundwater.

The method works to 60 feet in any soil type, including frozen ground that stops conventional equipment. Most importantly, it virtually eliminates the risk of utility strikes. When underground utility locating identifies a target, hydro-vacuum excavation exposes it without damage. The system operates in any weather condition, including extreme cold, which halts traditional excavation. For utility locations in California winter projects or anywhere else, it’s the gold standard.

OSHA 1926.651 Compliance Requirements

Federal law is explicit: estimated utility locations SHALL be determined PRIOR to excavation. Contact utility companies within established response times before starting work. When your excavation approaches marked utilities, exact locations SHALL be determined by safe means. Hand tools alone are NOT acceptable for this verification.

OSHA specifically approves hydro-vacuum excavation as an acceptable method for exposing underground utilities. This makes it both the safest and most compliant approach for winter projects. Trenches 4 feet or deeper require safe access and egress within 25 feet of lateral travel. A competent person must conduct daily inspections—non-negotiable requirements that protect workers and ensure proper coordination with utility locators.

Lighting and Visibility

Winter’s shortened daylight demands aggressive lighting solutions. Use generators to power trailer-mounted light towers at every excavation site. Never work in low-light conditions—the risk of workers falling into excavations increases dramatically when visibility drops. Poor lighting also makes it impossible to see utility markers placed by utility locating services.

Hire more workers per shift to maximize output during available daylight hours. Check progress frequently throughout the day to ensure work finishes before darkness. If underground utility locating reveals complex utility congestion, adjust schedules rather than rushing through dangerous low-light work. Proper lighting protects workers and ensures utility location markings remain visible throughout the project.

What Should You Do If You Strike a Utility?

Striking a utility during excavation is a life-threatening emergency that demands immediate, correct action. The Minnesota gas explosion killed four people within 40 minutes of the initial strike—frozen ground accelerates danger by trapping gas and preventing dissipation. Your response in the first minutes determines whether the incident becomes a minor interruption or a catastrophe.

Immediate Emergency Actions

STOP work immediately. Evacuate the area if you detect gas leaks or electrical hazards—no exceptions. Call 911 first, NOT just your supervisor. Gas migrating through frozen ground can reach nearby buildings within 40 minutes and explode. Every second counts. After calling 911, contact the utility company immediately to report the strike location and conditions.

Secure the area to prevent public access. Establish a perimeter and post warnings. Never attempt repairs yourself—damaged utilities require specialized emergency response teams. If gas is involved, evacuate and don’t re-enter any structures until cleared by professionals. Even if underground utility locating was performed correctly, strikes occasionally happen. Your emergency response determines the outcome.

Why Professional Locating Is Critical

The Common Ground Alliance maintains over 160 best practices covering damage prevention for utility locating services. These standards exist because professional underground utility locating dramatically reduces strike risk. When selecting utility locators, verify credentials thoroughly: check TRIR (Total Recordable Incident Rate), DART (Days Away, Restricted, or Transferred), LTIR (Lost Time Incident Rate), and EMR (Experience Modification Rate) safety records.

No OSHA violations in the past 5 years indicate a reliable safety culture. Demand written safety programs and comprehensive training for technicians. Companies with national presence ensure consistency across winter projects—whether you need a utility location service, standards remain high. The only true way to know underground infrastructure location is proper professional exposure using hydro-vacuum or similar non-destructive methods. Professional utility locating services cost a fraction of what utility strikes cost in repairs, delays, injuries, and lives.

Don’t Risk Winter Excavation Without Professional Utility Locating

Winter conditions demand expert underground utility locating—amateur approaches cost lives and millions in damages. Util-Locate provides professional utility locating services with certified technicians, advanced GPR and electromagnetic equipment, and comprehensive safety protocols designed for California’s winter challenges.

Our utility locators use hydro-vacuum excavation and cold-weather detection methods to accurately identify underground utilities even in frozen ground and snow cover. We maintain strict OSHA compliance and zero-tolerance safety standards that protect your workers, your project timeline, and your budget.

Schedule your utility location assessment before winter conditions worsen. Contact Util-Locate today for reliable underground utility locating that prevents strikes, saves money, and keeps projects moving safely through the harshest weather.

Call now or visit our website to request winter utility locating services.