Key Takeaways

- Low-bid utility locating creates false savings; the typical $20K-$25K cost reduction routinely becomes $200K-$500K+ in strike damages, delays, and liability claims.

- Locating quality directly correlates with strike risk; professional SUE (QL-B/A) reduces strike probability by 70-85% compared to surface-only or single-method approaches.

- Liability gets transferred back to contractors; low-bid providers use disclaimers, insurance caps, and vague contracts to shield themselves while leaving GCs exposed to full financial consequences.

- Legal precedent demands higher standards; courts increasingly reject surface markings as adequate care, establishing contractor liability even when utilities are marked (Titan Earthwork doctrine).

- Risk-adjusted value beats lowest price; when strike probability is factored in, professional SUE saves $34K-$56K on average mid-size projects despite higher upfront costs.

Commercial construction operates on thin margins. Every line item faces scrutiny. Competitive bidding drives subcontractor selection. But when it comes to subsurface utility locating, the lowest utility locating quote is almost always the highest risk. Low bids don’t just reduce service quality; they incentivize scope reductions that create catastrophic downstream costs, transferring liability directly back to general contractors and owners.

The numbers are stark: 167,000 utility strikes occurred in the U.S. in 2023. Nearly 50% happened because utilities were not located or were mislocated. Combined locating failures, facilities not marked (14.43%), plus facilities marked inaccurately (7.23%), account for 21.66% of all strikes, second only to failure to call 811. The total societal cost: $30 billion annually. Every strike is preventable. Most stem from a single procurement decision: choosing price over precision.

This article examines why the low-bid approach to utility locating consistently fails, how contractors and owners unknowingly assume massive liability, and what decision framework actually delivers best value when risk is properly accounted for.

What Does “Utility Locating” Actually Mean?

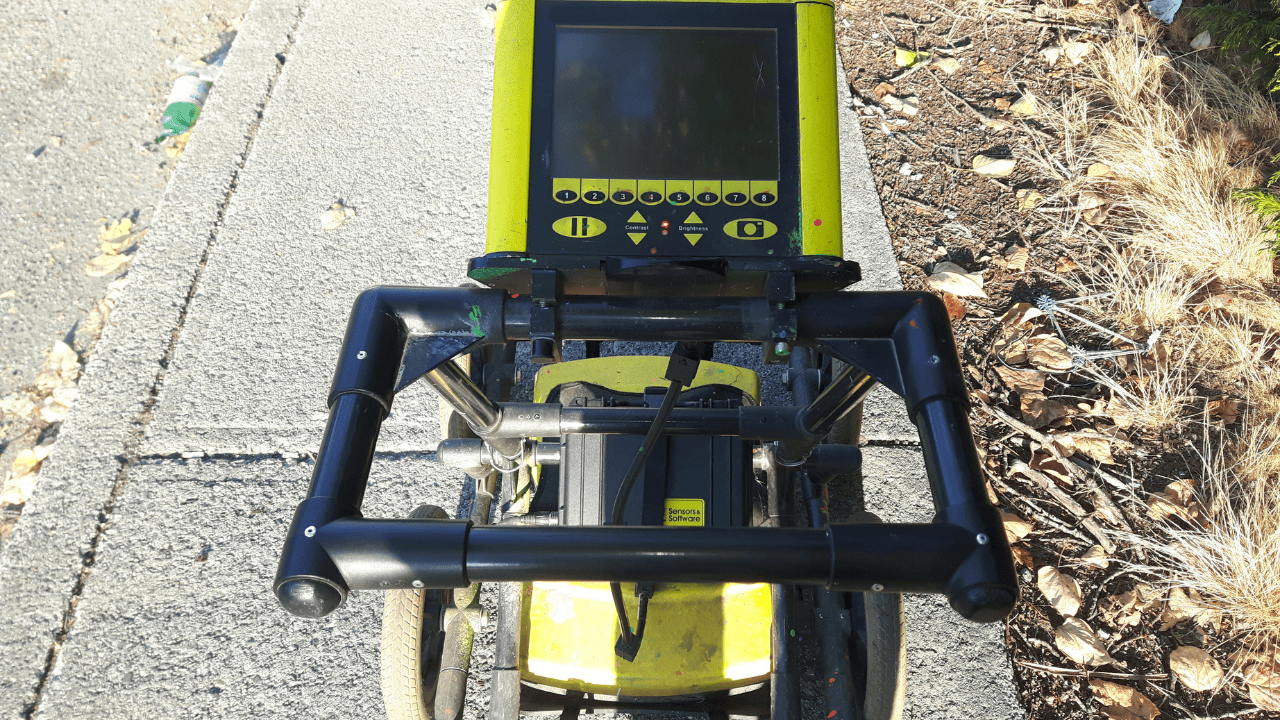

Not all locating services are equal. The spectrum ranges from free 811 surface marking to comprehensive Subsurface Utility Engineering (SUE). These aren’t variations of the same service; they’re fundamentally different products with vastly different risk profiles. Understanding utility locating quality differences is the first step to avoiding catastrophic mistakes.

| Service Level | What’s Included | What’s Missing | Typical Cost | Strike Risk |

| Surface-only 811 marking | Paint/flags, horizontal location estimate, single-method EM | Depth data, non-metallic utilities, CAD, documentation, verification | $0-$500 | 18-28% |

| Low-bid private locating (QL-D/C) | Surface marks, basic records check, minimal field time | Multi-method verification, QA/QC, CAD deliverables, depth confirmation | $5,000-$12,000 | 15-25% |

| Professional SUE (QL-B/A) | Multi-method field investigation, CAD deliverables, depth data, QA/QC, sealed report | None, comprehensive scope | $25,000-$50,000 | 3-8% |

Surface-only markings cannot detect non-metallic utilities, PVC water lines, fiber optic cables, concrete conduits. Single-method electromagnetic (EM) locating is blind to anything non-conductive. Without CAD deliverables, there’s no design coordination and no permanent record. Without depth data, excavation is a gamble. The Connecticut electrocution case proves the point: utilities marked 7 feet 8 inches from actual location, $2 million jury verdict, worker permanently disabled.

The False Economy: How Low Bids Create Massive Hidden Costs

The $20,000 “savings” from choosing low-bid locating routinely costs projects $200,000 to $500,000+ in strikes, delays, and damages. The math is brutal and consistent across project types. The utility strike prevention ROI from professional services proves decisive when risk is properly calculated.

| Metric | Low-Bid Locating | Professional SUE | Impact |

| Upfront cost | $8,500 | $32,000 | Appears to save $23,500 |

| Strike probability | 18-28% | 3-8% | 3-9x higher risk |

| Average strike cost | $450,000 | $450,000 | Same consequence if it happens |

| Risk-adjusted cost | $81,000-$126,000 | $13,500-$36,000 | Hidden risk multiplier |

| True total cost | $89,500-$134,500 | $55,500-$78,000 | Professional SUE saves $34,000-$56,500 |

The indirect costs tell the real story. Repair costs are just the beginning; indirect and social costs run 29 times direct repair costs. Schedule delays trigger liquidated damages. Insurance claims spike premiums 20-50% for years. Unreliable location data creates a $50-100 billion annual drag on the U.S. economy. Meanwhile, professional SUE delivers documented ROI of $4.62 to $22.21 for every dollar spent. For contractors seeking San Diego private utility locating services, understanding this cost multiplier is critical to project success.

How Low-Bid Providers Achieve Low Prices (Scope Shortcuts):

- Surface-only methods can’t detect non-metallic utilities

- Single-method approach (EM only) misses plastic, fiber, and concrete

- No QA/QC or verification steps

- No CAD deliverables or permanent documentation

- Liability disclaimers + insurance caps at service fee amount

- No depth verification, forces blind excavation

How Risk Gets Transferred Back To You

Low-bid locators know their service is inadequate. They protect themselves with contractual mechanisms designed to shift every dollar of liability to the general contractor and owner. You think you’re buying risk reduction. You’re actually buying a risk assumption.

Liability Transfer Mechanisms in Low-Bid Contracts:

- Accuracy disclaimers: “Marks are estimates only; not warranted accurate.”

- Liability caps: Limited to service fee ($5K-$10K) against $500K+ strike costs

- No Professional Liability insurance: Only General Liability, which doesn’t cover professional errors

- No standards compliance: Don’t reference ASCE 38, so no measurable quality baseline

- Broad indemnification: Contractor must hold locator harmless

The legal precedent is unforgiving. In Titan Earthwork, LLC v. City of Federal Way (403 P.3d 884), the court held the contractor strictly liable for damaging underground utilities, even though utilities were marked through the one-call system. The ruling established the “red flag doctrine”: contractors cannot blindly rely on utility markings when circumstances suggest they may be incomplete or inaccurate. Courts increasingly expect professional-grade subsurface investigation as the standard of care. Utility mapping helps planning for smarter projects by providing verified data that meets legal standards.

What this means: Even with 811 compliance and paint on the ground, the GC carries full liability when strikes occur. The low-bid locator walks away with their $8,500 fee. The contractor pays for emergency repairs, project delays, liquidated damages, worker injuries, OSHA violations, insurance claims, and years of litigation. The $23,500 “savings” becomes a $500,000 loss. Every time.

Real-World Consequences: Case Examples

Theory becomes reality when excavators hit the ground. These cases aren’t outliers; they’re patterns repeated daily across commercial construction sites. The common thread: inadequate locating creates consequences that dwarf any initial cost savings.

Case 1: Connecticut Electrocution, $2M Verdict

Commercial water line replacement, Naugatuck, Connecticut, June 2019. The contractor followed protocol: called 811, waited for a professional locator, received surface markings. The excavator bucket cut an underground power line. Worker Keven Shepard, 56, suffered severe electric shock in the trench. The investigation revealed the power line was marked 7 feet 8 inches from its actual location.

Eversource Energy had contracted the U.S. Infrastructure Company (USIC) through the 811 system. The utility claimed the contractor had “complete control” and should have “taken necessary precautions.” The jury disagreed. They found the utility and its locator negligent for failing to adequately mark underground facilities. Verdict: $2 million for permanent nerve and muscle damage, injuries to back, hips, knees. The worker can no longer perform his job.

Key lesson: Statutory compliance doesn’t equal safety. Even with 811 notification and contracted professional locators, inaccurate markings create catastrophic liability. The verdict represents only personal injury, project delays, emergency response, and litigation costs are additional.

Case 2: Urban Redevelopment, $510K In Damages

Mid-rise commercial building, dense urban area. The GC selected low-bid locating at $8,500, saving $23,500 versus professional SUE. The project immediately encountered three strikes in six weeks:

- Week 2: Unmarked telecommunications conduit bank, not detected by surface-only EM locating. Emergency stop-work order. 5-day delay, $85,000 repair.

- Week 4: Non-metallic water line missed by single-method approach. 7-day delay, flooding damage.

- Week 6: Abandoned gas line not in utility records, requiring environmental remediation. Major redesign, 23-day total project impact.

Total cost: $510,000+ in liquidated damages ($10K/day), emergency repairs, re-mobilization, engineering redesign, legal fees, and insurance premium increases. The initial $23,500 “savings” created a cost multiplier of 21.7x. Professional SUE would have identified all three conflicts pre-excavation through comprehensive multi-method investigation and records research. Design could have been adjusted. Zero strikes, zero delays. Net savings: $486,500. This is precisely how utility mapping prevents construction delays, by identifying conflicts before excavation begins.

The broader data confirms these aren’t isolated incidents: 64% of contractor strikes involve utilities located more than 2 feet outside the marked area. Over 20 years of documented cases: $1.7 billion in property damage, thousands of injuries, hundreds of deaths, all preventable through adequate subsurface investigation.

What Should Be Non-Negotiable In Your Scope

A locating contract without enforceable specifications is a blank check for risk. Before price comparison, define what you’re actually buying. These minimum requirements separate professional investigation from liability transfer.

Minimum Requirements to Reduce Risk:

Scope Definition:

- Written boundary map showing exact investigation area

- Explicit list of utility types included (and excluded)

- Method disclosure (EM + GPR minimum for comprehensive work)

- Deliverables specified: CAD format, photo log, field notes

Verification Requirements:

- Multi-method verification where needed (EM + GPR, not EM alone)

- Conflict resolution process when field doesn’t match records

- Daylighting triggers: when test pits required (depth conflicts, high-consequence utilities, drilling operations)

Accountability:

- Professional Liability (E&O) insurance: $1M+ minimum

- ASCE 38 compliance with stated Quality Level (QL-B minimum for complex sites)

- Sealed engineering report (professional takes responsibility)

Critical callout on depth data: If depth is NOT provided, it must be stated explicitly and risk managed through hand digging or test pit verification. Never assume depth is included if not specified. Horizontal location without depth data forces blind excavation, the exact condition that causes strikes. Contractors searching for cheap utility locating options in San Diego often discover these scope gaps only after strikes occur.

How To Compare Quotes Without Missing Hidden Risk

Price comparison without standardized scope is meaningless. A $10,000 quote for surface-only marking isn’t comparable to a $35,000 quote for comprehensive SUE, they’re different products with different risk profiles. Follow this process to make apples-to-apples comparisons that reveal true value.

5-Step Apples-to-Apples Comparison:

- Standardize Scope for All Bidders

- Same boundary, same utilities, same deliverable requirements

- Forces comparable pricing instead of scope manipulation

- Require Method and Deliverable Disclosure

- What equipment? Where will each method be used?

- What format is CAD? What documentation is provided?

- Verify Insurance and Standards

- Request certificates: Professional Liability AND General Liability

- Confirm ASCE 38 compliance in writing with stated Quality Level

- Normalize Pricing

- If Provider A includes CAD ($4K) but Provider B doesn’t, add Provider B’s CAD upcharge

- Compare total cost for equivalent scope, not cherry-picked base fees

- Score on Quality, Not Just Price

- Weight: Technical approach (40%), qualifications (30%), insurance/standards (20%), price (10%)

- Choose highest quality score that meets minimum requirements

Calculate Risk-Adjusted Value: Quality score ÷ (Price ÷ $10K)

- Low-bid with weak scope = low quality score ÷ low price = poor value

- Professional SUE = high quality score ÷ higher price = best value

The lowest price doesn’t win when you account for the cost of failure. A $12,000 service with 25% strike probability carries $112,500 in expected loss. A $35,000 service with 5% strike probability carries $22,500 in expected loss. The “expensive” option saves $90,000 in risk-adjusted cost. Smart procurement maximizes value, not the lowest initial outlay.

Red Flags That Should Stop The Award

Some quotes aren’t just low, they’re designed to fail. These warning signs indicate a provider plans to deliver minimal work while maximizing legal protection. Any single item should disqualify the bid.

Deal-Breakers in a Low-Bid Quote:

- Refuses written scope boundaries/exclusions

- Preserves the ability to claim “that wasn’t included” after a strike occurs

- No CAD or depth data with no mitigation plan

- Can’t coordinate design; can’t verify clearances; no permanent record for future work

- No Professional Liability insurance or refuses proof

- Zero financial accountability for professional errors and omissions

- No ASCE 38 or standards reference

- No measurable quality baseline; “locating” becomes undefined and unenforceable

- Vague contract language (“marking only,” “as requested,” “not responsible for accuracy”)

- Liability avoidance without a defined process or deliverables

- Unrealistic turnaround (48 hours for a complex urban site)

- Either planning minimal work or missing the deadline, both create project risk

These aren’t negotiable points; they’re fundamental requirements for a service that actually reduces risk. A provider unwilling to define scope, demonstrate capability, or accept accountability isn’t selling locating services. They’re selling liability transfers disguised as a low price.

When Is The Low-Cost Option Acceptable?

Limited scenarios exist where basic locating approaches are reasonable, but only with explicit safeguards that compensate for reduced scope. Accept lower cost only when limitations are documented and field-level risk controls are mandatory.

Acceptable Scenarios:

- Greenfield sites, low congestion, shallow work (<3 ft depth)

- Strong recent as-built records with field verification

- Non-critical utilities, low consequence of strike (irrigation, landscape lighting)

Required Safeguards Even for Basic Work:

- Written scope limits + explicit exclusions (states what IS and ISN’T included)

- Photo log and field notes (minimal documentation creating accountability)

- Trigger-based daylighting plan (depth >3 ft, within 10 ft of gas/electric)

- Remark policy (marks refreshed every 14 days or after weather events)

- Hand digging protocols within tolerance zone (±24 inches of any mark)

- Basic Professional Liability insurance (even if lower limits than complex projects)

Critical point: You can accept a reduced scope if limitations are explicit and field-level safeguards compensate for missing verification steps. You cannot accept vague, undocumented, unaccountable service, regardless of site conditions. The difference between “basic” and “inadequate” is transparency and risk management planning, not price.

The Best-Value Rule Of Thumb

Core principle: If the quote for utility locating is low because it removes verification, documentation, CAD/depth data, or accountability, risk goes up exponentially, not linearly.

Best Value Formula:

- Match investigation rigor to project risk (greenfield ≠ urban infill)

- Demand transparency (written scope, method disclosure, deliverables list)

- Verify accountability (E&O insurance + ASCE 38 compliance)

- Evaluate risk-adjusted cost, not sticker price

The data proves the value: Professional SUE delivers ROI of $4.62 to $22.21 per dollar spent. Net savings average $34,000 to $56,500 on typical mid-size commercial projects. Strike risk reduction: 70-85% compared to low-bid approaches. These aren’t projections; they’re documented outcomes across thousands of projects.

Contractors who consistently deliver on time and on budget treat utility locating as core risk management, not a procurement commodity. They understand that the “expensive” quote is usually half the true cost when risk is properly factored in. The lowest price is only the right price when scope, accountability, and safeguards are equal. They rarely are.

Don’t gamble with your project timeline and budget. Get professional subsurface utility engineering that actually reduces risk. Contact Util-Locate for a comprehensive scope proposal that prioritizes certainty over cheap bids.