Dive into the future of underground utility locating. Discover emerging technologies and strategies shaping the industry. Stay ahead with insights into how utility locating is evolving for more accurate results.

In construction, locating private utilities and mapping underground infrastructure are very imporatnt. Welcome to the subterranean frontier, where the pulse of development is intricately connected to the accurate detection of gas lines, telephone cables, fiber optics, and power lines.

As we stand on the cusp of technological innovation, the spotlight is on the future of underground utility locating, a realm where precision meets the demands of a rapidly evolving urban landscape.

The tools of the trade are evolving, the stakes are higher than ever, and the narrative of utility locating is being rewritten with each groundbreaking advancement. Learn more as we explore the trends that will shape this dynamic industry, blending the excitement of discovery with the unwavering commitment to safety and efficiency.

Embrace Advanced Technologies

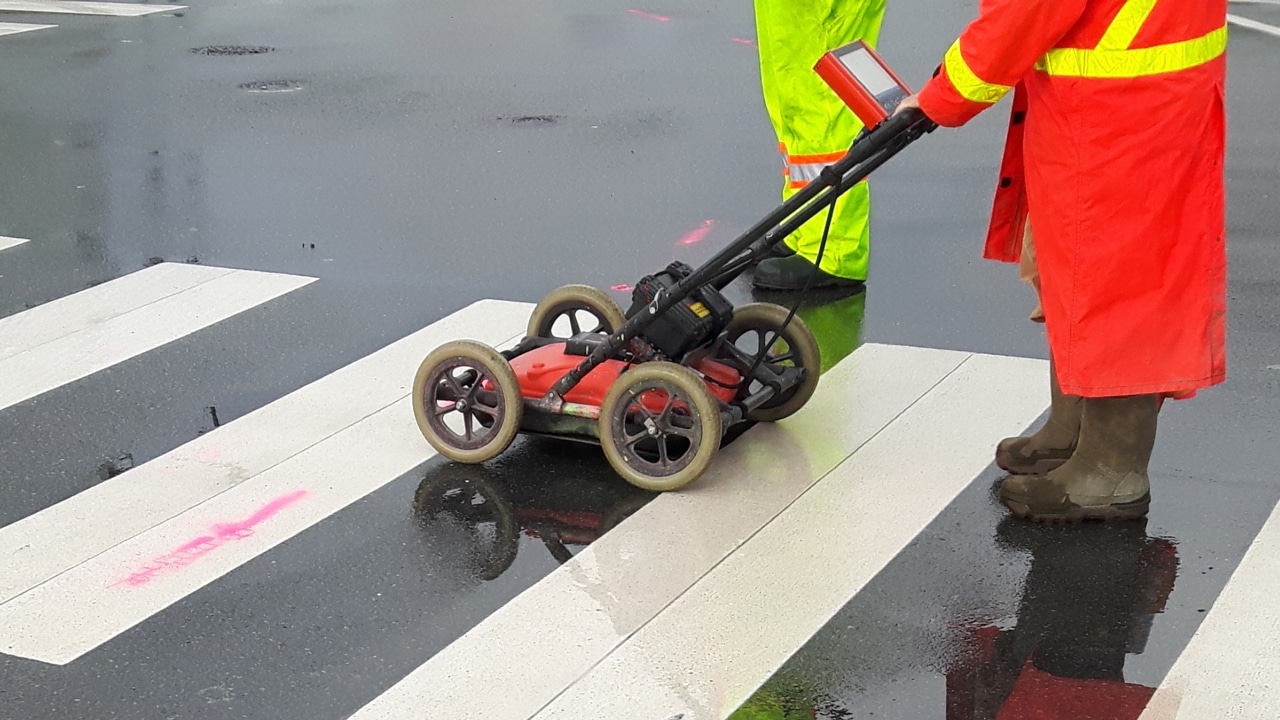

In the quest for more precise utility locating, industry players are increasingly turning to advanced technologies. Ground-penetrating radar (GPR) and electromagnetic field detection are emerging as game-changers, providing valuable insights into subsurface utilities.

The integration of innovative utility locator systems not only enhances accuracy but also contributes to worker safety by minimizing the risk of accidental damage to gas lines, telephone lines, fiber optic cables, and power lines.

Meet the Rising Demand

The growing demand for utility locator services can be attributed to the booming construction industries and the increasing complexity of underground infrastructure. As the market for utility locators expands, major players are investing heavily in research and development to stay ahead.

Government initiatives and investments are also playing a pivotal role in fueling market growth, emphasizing the importance of efficient utility mapping for sustainable development.

Enhance Efficiency through Electromagnetic Waves

Innovations in utility locating extend beyond traditional methods, with a notable focus on electromagnetic waves. Metallic utilities, often challenging to detect accurately, can now be located with unprecedented precision.

This not only prevents potential damage to pipelines but also ensures efficient utility mapping, addressing the critical need for infrastructure development without compromising safety.

Mitigate Risks and Accidental Damage

One of the central concerns in underground utility locating is the risk of accidental damage during construction activities. Gas lines, telephone lines, and fiber optic cables are particularly vulnerable.

The incorporation of sophisticated utility locator systems, guided by electromagnetic field detection and GPR, minimizes these risks. This not only protects critical infrastructure but also reduces costly downtime associated with repairs.

The Role of Private Utility Locating

Amidst the evolving landscape, private utility locating services are gaining prominence. With the market recognizing the limitations of traditional utility location services, the demand for specialized private providers is on the rise.

These entities bring a heightened level of expertise, often surpassing generic utility location services, and play a crucial role in catering to specific needs within the construction and infrastructure development sectors.

Government Investment and Regulatory Frameworks

Government investment remains a driving force behind the transformative trends in underground utility locating. Stringent regulatory frameworks are being established to ensure adherence to safety standards and prevent damage to underground infrastructure.

This not only safeguards public interests but also fosters a conducive environment for continued market growth.

3D Utility Mapping

Advancements in technology have given rise to 3D utility mapping, providing a comprehensive visualization of subsurface utilities. This innovative approach goes beyond traditional two-dimensional mapping, offering a more detailed representation.

By incorporating this three-dimensional perspective, utility locators can identify potential conflicts and optimize the layout of underground infrastructure, further minimizing the risk of accidental damage.

Artificial Intelligence Integration

The integration of artificial intelligence (AI) is transforming how underground utility locating services operate. AI algorithms can analyze vast datasets from various sources, including ground-penetrating radar and electromagnetic field detection, to provide real-time insights.

This not only enhances the accuracy of utility mapping but also enables predictive analytics, allowing for proactive measures to prevent potential damage to gas lines, fiber optic cables, and other critical utilities.

Internet of Things (IoT) Sensors for Monitoring

The utilization of IoT sensors in underground utility locating introduces a new dimension to monitoring and maintenance. These sensors can be embedded in utility infrastructure to provide continuous data on the condition of pipelines, cables, and other assets.

This proactive approach allows for early detection of issues, reducing the likelihood of unexpected failures and enhancing overall system reliability.

Collaborative Data Sharing Platforms

The future of underground utility locating is marked by increased collaboration through data-sharing platforms. These platforms enable various stakeholders, including utility service providers, construction companies, and government agencies, to share and access critical information seamlessly.

This collaborative approach fosters efficiency, reduces redundancies, and ensures a more streamlined process for utility mapping and location services.

Enhanced Communication Systems

Communication is a key factor in avoiding accidental damage to underground utilities. Future trends in utility locating involve the development of enhanced communication systems that facilitate real-time information exchange between construction teams, utility locators, and project managers.

This ensures that all parties involved are well-informed about the location of subsurface utilities, contributing to a safer working environment.

Drone Technology for Aerial Surveys

Incorporating drone technology into underground utility locating processes provides a unique vantage point. Drones equipped with specialized sensors can conduct aerial surveys, offering a bird’s-eye view of the construction site.

This not only aids in identifying potential challenges but also enhances the overall efficiency of utility mapping by covering large areas in a shorter time frame.

Embrace Tomorrow’s Groundbreaking Trends with Util-Locate Today

The fusion of advanced technologies, collaborative approaches, and a commitment to safety is reshaping how we navigate the intricate web of subsurface utilities. Ready to uncover the future? Make Util-Locate your partner in underground utility locating today!

For those ready to embark on projects that demand precision and reliability, there’s a partner at the forefront of the private utility locating revolution: Util-Locate. With a proven track record, cutting-edge technologies, and a dedication to excellence, Util-Locate stands as a beacon in the ever-changing world of underground utility locating.

Navigate the subterranean frontier with confidence. Reach out to Util-Locate for industry-leading utility locating services that promise accuracy, efficiency, and a commitment to the safety of your projects. Discover tomorrow’s solutions with confidence — contact us at 866-638-1075 today!